H₂ / Biofuels

Low-NOx

Hot water boiler

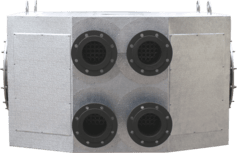

Unimat hot water boiler UT-M

The highly efficient UT-M is a three-pass boiler designed for 750 to 19,200 kW of heating at up to 16 bar. Its various output sizes and temperature ranges up to 190 °C enable flexible operation for countless process heat and heating applications.

- Efficient heat and process heat from 750 to 19,200 kW for low running costs and emissions

- Compact design for easy positioning and quick heating

- Flexible use for industrial, commercial and district heating applications with temperatures up to 190 °C

- Project-specific control solutions and optional real-time monitoring

- Complete system from a single source, low-emission or CO2-neutral customer-specific operation possible

- Proven and maintenance-friendly construction for a long service life and reliability